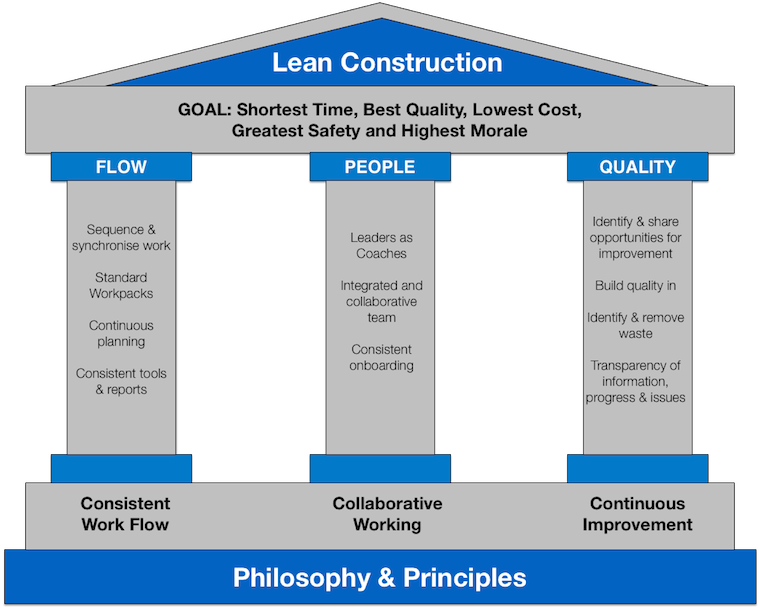

Lean is process improvement – how to get from point A to point B

How does Lean work?

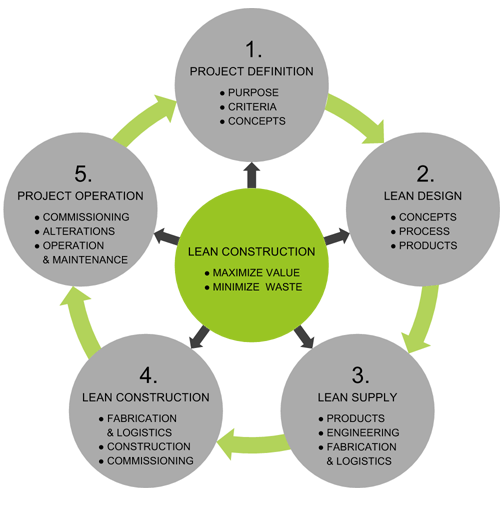

In the construction world the Lean Method is very applicable and goes far to ensure a project comes in on schedule and at or below budget. It starts with team selection and continues through design, budgeting, material procurement and construction.

Each of these steps affects the other and contributes to the project goal of eliminating waste and maximizing value for the client.

Newport Construction & Lean

The Lean method of construction is a fairly new approach to managing and organizing a construction project.

Rob first became interested in Lean when he was in charge of the formation of the AFSO21 (Air Force Smart Operations for the 21st Century) program at Charleston Air Force Base. This organization took the principles of the Lean methods from the world of manufacturing in an effort to apply it to other areas of operation. Rob worked with Operations groups, medical personnel, contracting and maintenance folks to introduce efficiency in their daily processes while decreasing their daily costs.

Eliminate Waste

The goal from the outset of every project is to eliminate waste in any process. This includes waste of time, waste of manpower, waste of space and waste of money. Below are the most common types of waste in construction in further detail:

Defects

Efforts caused by rework, scrap

and incorrect information.

Overproduction

Production that is more than needed

or before it is needed.

Waiting

Wasted time waiting for the

next step in the process.

Non-utilized Talent

Underutilizing people’s talent,

skills and knowledge.

Transport

Unnecessary movement of

objects and materials.

Inventory

Excess products and materials

being processed.

Motion

Unnecessary movement by people

(e.g. walking).

Extra-Processing

More work or higher quality,

than is required by the customer.

Quality

The better the quality of the work and the workers the less rework that will occur. Newport Construction has processes in place that require continuous quality inspections that are documented and are required to be addressed and approved to move on.